Introduction

The client is a reputed leather manufacturer with large manufacturing unit that deploys a range of sophisticated machines in the process. They were looking for an asset monitoring system for their manufacturing machines operating at the factory, to control the cost and improve productivity. The need to monitor each of their machines.

The Problem Outline

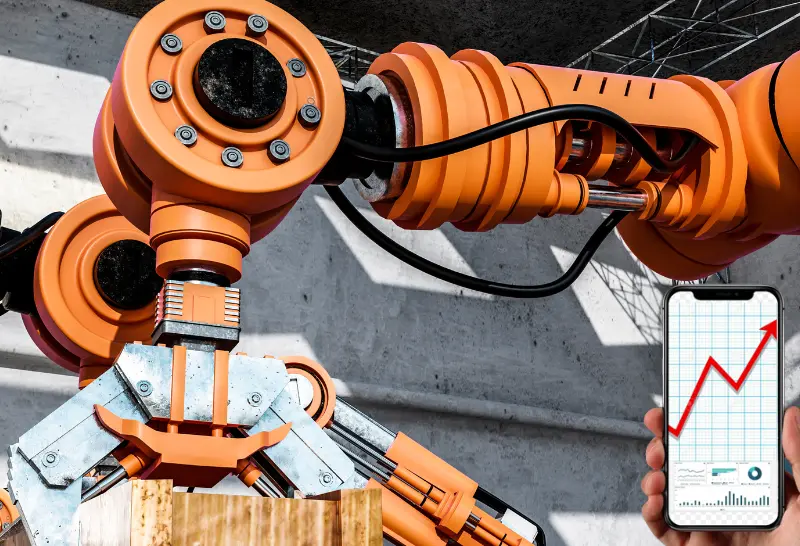

Our technical team made a direct visit to see the possibilities in implement the IoT solution that would solve their pain points and requirements. As a leading leather manufacturing company they deployed various types of machines for processing and manufacturing types of leather. The client needed a remote diagnostic tool to monitor health and usage of the machine involved in production. The proposed system should help via data analytics to know about maintenance details to improve productivity.

They needed to monitor the Hot Pressing Machines, Screw Air Compressors, Wet finishing & Dry finishing drums, etc. They wanted to know how much electricity is consumed by a particular machine which is the major paint point in production cost. They wanted to cut down on their electricity bill. So far they calculating the performance of the production line and not the performance of the individual machines which is a grey area. They required to monitor the running of the machines whether ON or OFF at a point of time.

The Solution Summary

Our cloud-based IoT solution makes it convenient for the client to monitor different machines at different locations. This solution can deliver infrastructure monitoring and provide end-user experience that is needed for a great digital experience for users. The web-based machine monitoring and management platform measures current values of parameters of each machine and group of machines to give visibility and to evaluate the performance over a period of time that can be defined. Power consumption of machines in production line can be easily monitored with IoT devices installed.

The IoT application for machine monitoring can constantly monitor the critical parameters, along with the trends, making it easy for managers to take data-driven (informed) decisions. The application can monitor on 24×7 basis, in real-time, on the IoT platform provided by Trinetra tSense. The application has benefits like:

- Know your assets performance in real-time

- Finds the trend in faults and discrepancies

- Increases machine health and reduces the maintenance cost

- Overall Cost Savings for the unit in power and resources

- Performance of machines analysed and reports generated immediately.

- Value Addition to improve productivity

Outcome / Result

- Remote monitoring gives 24×7 visibility of assets at remote locations

- Instant notification/alerts on abnormalities and hazards

- Remote monitoring of machine health increases uptime and productivity

- Helps in better energy management of assets for company

- Overall improved machine performance

Our customisable IIoT solution is cloud hosted on a single unified software platform. Purpose-based sensors deployed can monitor numerous parameters to generate the data needed for remote diagnostics and data analytics. It improves overall performance of the machines and productivity of the manufacturing unit.