IoT-driven Real-time Remote Machine Monitoring system optimizes manufacturing productivity and service performance. Businesses can remotely track machines and equipment across multiple sites, ensuring smooth operations and timely maintenance, practically improving ROI using this solution. This cloud-based solution detects anomalies and addresses issues like fuel/oil wastage, theft, overheating, unexpected breakdowns and more. Processed data across the system becomes a valuable OEM resource.

Solution Highlights

- Operations Monitoring: Real-time tracking of machine performance and production.

- Machine Availability: Continuous monitoring of machine uptime.

- Preventive Maintenance: Predictive maintenance to prevent breakdowns.

- Condition Monitoring: Ongoing assessment of machine health.

- Resource Utilization: Efficient use of materials and resources.

- Location Tracking: Real-time tracking of machine or asset locations.

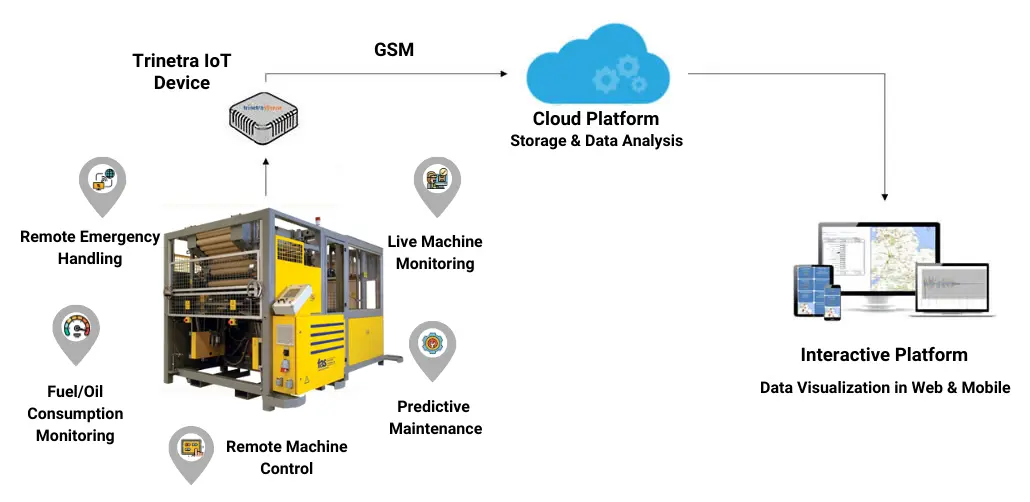

System Architecture

Parameters Monitored

Temperature, vibration, sound, RPM, energy, tank levels, voltage, frequency, location.

Key Features

- Intuitive Dashboard for real-time overview

- Instant alerts/notifications for proactive response

- Energy monitoring system for cost-savings

- Real-time Location tracking for portable machines

- Multi-site Remote Monitoring for simultaneous overview

- Centralise Security and surveillance for machines

- Spare Parts Scheduling based on real-time insights.

- Scheduled Reports for easy analysis

- Data-driven Analytics for decision making

Benefits of the IoT-powered Intelligent Machine Monitoring Solution

- Machine Availability & Optimized Resource Management

- Robust Data Analysis

- Automated Machine Condition Assessment

- Seamless System Integration

- Remote Site Oversight

- Customization for Comprehensive Machine Management

- Machine Downtime Tracking

- Predictive Maintenance of Machines

- Built-in Performance Indicator

- Assists Production Monitoring

Monitor downtime and idle periods for efficient resource management, minimizing wastage.

Utilize informative graphs to transform complex data, enhancing understanding and driving operational improvements.

Evaluate equipment health by analyzing factors like temperature, pressure, and vibrations. Automate data management to ensure optimal performance.

Integrate with existing systems effortlessly, ensuring a smooth transition and coexistence with established processes.

Monitor remote sites with enhanced machine connectivity for real-time insights and comprehensive control.

Tailor the software for comprehensive machine management, covering maintenance tracking to performance optimization.

Our IoT-based Machine Monitoring software heralds a new era of industrial efficiency and productivity. By seamlessly combining cutting-edge IoT technology with user-centric design, we empower businesses to elevate their operations, reduce downtime, and make data-driven decisions. The journey towards smart manufacturing begins here.

Highlights of the Application

Utilize IoT-enabled sensors to prevent unscheduled downtime, offering real-time insights and cost savings.

Implement data-driven IoT solutions for simplified KPIs, performance insights, and optimized equipment performance.

Access real-time performance indicators for immediate actions, ensuring proactive responses even for remote systems.

Track real-time product flow on conveyor systems and assembly lines, ensuring timely production quotas and lean management.

Remote Machine Monitoring as the stepping stone to Industrial IoT

Industries rely on machines for production, underscoring the need for their good health by maintenance. A pivotal component of IoT adoption, this remote machine monitoring solution establishes a communication network, enabling holistic plant data analysis. Beyond monitoring, it offers real-time data, predictive maintenance, automation and support, aligning with heightened productivity and maintenance goals.