The Internet of Things drives digital transformation across industries with enhanced connectivity and data analytics. In cold storage, maintaining precise temperature and humidity is paramount. Real-time monitoring, backed by predictive analytics, ensures safety and quality for perishable goods.

Key Challenges:

Cold storage facilities face several challenges that can impact the integrity and safety of stored goods

- Fluctuations in temperature: Even minor temperature variations can spoil food, pharmaceuticals, or chemicals, leading to significant financial losses.

- Manual monitoring: Not just time-consuming, but conventional methods of monitoring are labor-intensive and hence prone to errors, with noticeable delays.

- Energy Consumption: Cold storage demands high energy and inefficiencies can be costly.

- Regulatory compliance: Adhering to rigid requirements around storage conditions is not a choice and noncompliance could have consequences in the form of penalties and product recalls.

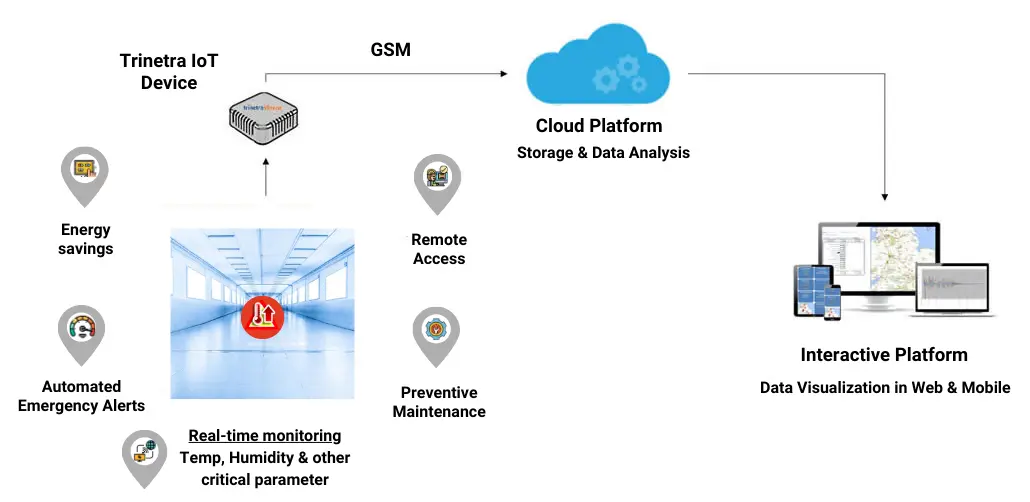

System Architecture

Solution Offering:

IoT-based monitoring capabilities of cold storage facilities ensure a complete and automated solution with the following features:

- Continuous Monitoring: Instant real-time monitoring can ensure that all the crucial parameters, such as temperature and humidity in a cold storage facility, are under surveillance.

- Data-Driven Analytics: Advanced analytics detect anomalies and trends, providing insightful data on the performance and conditions within the cold storage facility.

- Alerts: Instant alerts are triggered via SMS, email or app notifications if conditions deviate from the set parameters, ensuring prompt response to potential issues.

- Predictive Maintenance: Predict possible failures in equipment by analyzing performance data and hence prescheduling maintenance.

- Remote Access: Cloud-based platforms provide remote monitoring and control, so managers are able to have an overview of various facilities from one dashboard.

- Energy Management: The analytics of energy use through IoT can be optimized to help reduce consumption and energy spending while maintaining optimal storage conditions.

- Regulatory Compliance: Automated data logging and reporting features thereafter ensure that all industry standards and regulatory compliance are met, making audits and inspections simple.

Applications:

The applications of IoT cold storage monitoring systems are multiuse in nature and are seen in several industries. Some of the examples are as follows:

- Food and Beverage: Quality, freshness, and safety of produce, dairy, meat, and seafood.

- Pharmaceuticals: Guaranteeing the efficacy and safety of temperature-sensitive medications and vaccines.

- Logistics and Supply Chain: Ensuring proper conditions for transportation; prevention of spoilage and maintenance of product integrity.

- Chemical and Industrial: Storing chemicals and industrial products in the right environmental conditions.

- Agriculture: The system provides several sets of conditions for the maintenance of proper conditions during the storage period and avoids alteration in quality of harvested crops, thus avoiding post-harvest losses.

IoT-based cold storage monitoring systems revolutionize temperature-sensitive environment management. Utilizing real-time data, predictive analytics and remote access, they enhance the reliability, efficiency and safety of cold storage operations. Only those adopting these advanced systems can ensure their perishable goods are stored and delivered in optimal condition.