The Modbus protocol is a popular standard for industrial automation systems and is extensively employed to enable communication among sensors, programmable logic controllers (PLCs) and computers. Modbus is a simple and robust protocol designed for transmitting data between devices over serial communication lines.

The protocol was first published by Modicon (now Schneider Electric) in 1979. This protocol is one of the oldest and probably the most popular automation protocol in the area of automation process and has since become a de facto standard for connecting various devices in industrial environments. Thus Modbus protocol plays a key role in IoT (Internet of Things) for several reasons and we see them below.

-

Wide Adoption of the protocol

Modbus has been widely adopted and implemented in industrial automation and control systems for several decades. Many existing devices and systems in industrial environments already support Modbus, making it a natural choice for integrating these devices into IoT solutions. This allows for easy connectivity and interoperability between legacy devices and modern IoT systems.

-

It is Simple and Lightweight

Modbus is a relatively simple and lightweight protocol, which makes it suitable for resource-constrained IoT devices with limited processing power, memory, and bandwidth. Its simplicity allows for efficient communication and minimizes the overhead associated with protocol implementation.

-

It is Flexible

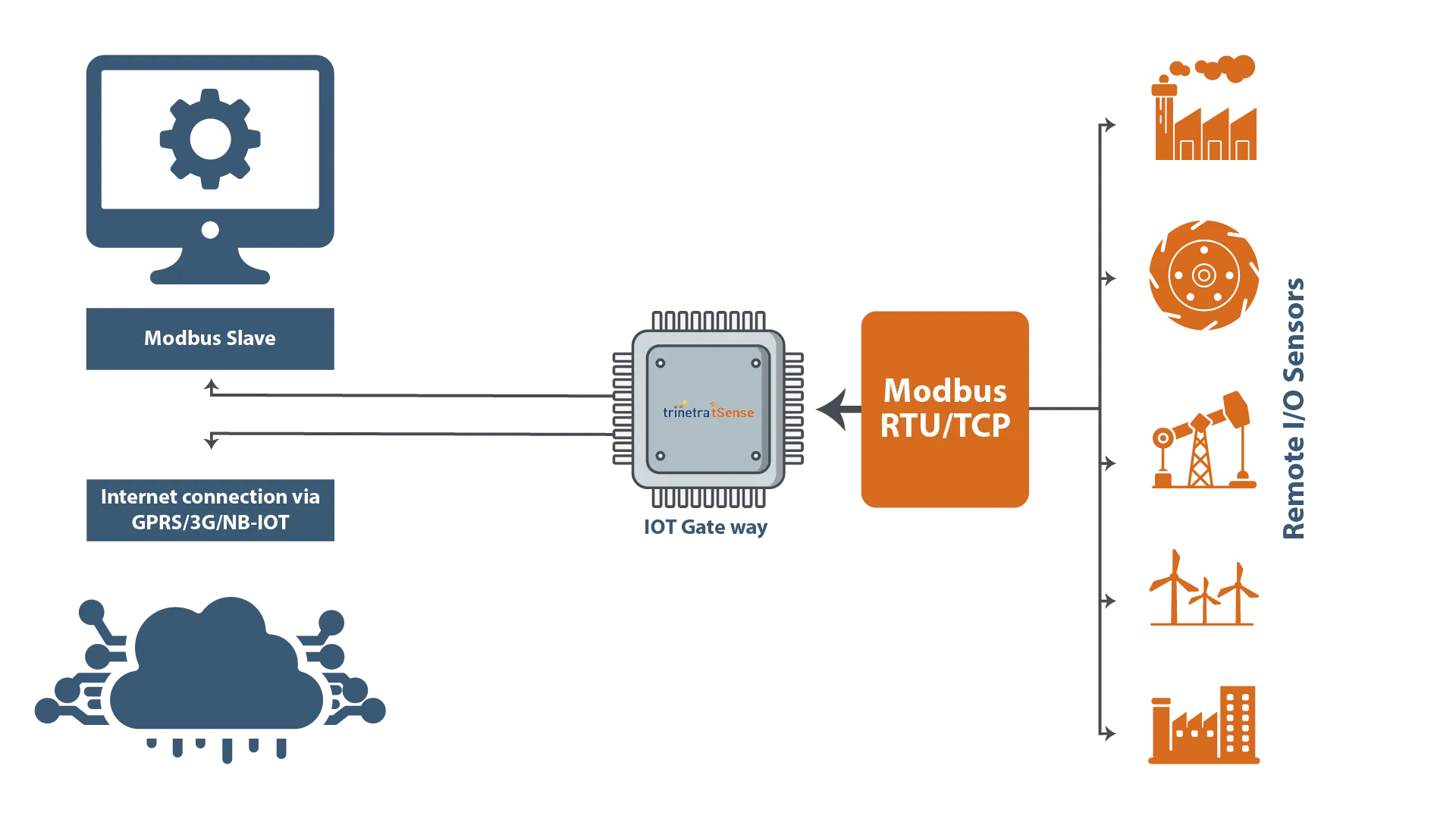

Modbus supports both serial communication (such as Modbus RTU) and Ethernet communication (such as Modbus TCP). This flexibility enables the integration of a wide range of devices, such as sensors, actuators, and controllers, into the IoT platform or network. The protocol can also be easily used on different platforms, including microcontrollers, embedded systems, and industrial gateways.

-

It is Scalable

Modbus supports a master-slave architecture, where a single master device can communicate with multiple slave devices. This scalability allows for the creation of large-scale IoT networks where a central device can monitor and control multiple devices simultaneously.

-

Advantage of Interoperability

Modbus is an open protocol, meaning that its specifications and documentation are publicly available. This openness promotes interoperability between different vendors and devices, as they can implement the protocol based on the standard specifications. This interoperability simplifies the integration of devices from different manufacturers into IoT ecosystems.

-

Integration with Legacy Devices

Many industrial environments still rely on legacy devices that communicate using Modbus. By using Modbus in IoT solutions, such legacy devices can be easily integrated and connected to modern IoT platforms, enabling data gathering, remote monitoring, and remote control.

-

Offers a Mature Ecosystem

Modbus has a mature ecosystem with a wide range of tools, libraries, and software support available. This includes Modbus gateways, software libraries for implementing Modbus communication, and configuration tools for setting up and managing Modbus networks. The availability of the resources needed for Modbus protocol simplifies the development and deployment of IoT solutions.

Owing to not just its widespread adoption, but also its simplicity, flexibility, scalability, interoperability, and mature ecosystem, the protocol Modbus plays a key role in integrating legacy devices and enabling seamless communication in IoT deployments and projects, within industrial environments.

Trinetra T-sense offers secured and scalable IoT software solutions. Our custom-made IoT solutions delivered for various clients show our relevant expertise and experience in IIoT projects. Request a Demo Today.