INDUSTRY: Original Equipment Manufacturer

Cost Efficient unified solution on powerful software platform helps quick Return on investment and data-based decision making.

A unified platform to manage all parameters, to monitor it centralized on machine quality, to reduce maintenance cost and for quick access to remote diagnostics tools on each asset.

Introduction

The client who approached us is a successful Original Equipment Manufacturer, reputed makers of Power & Distribution Transformers who is into assembling & distribution of Industry based equipment. They serve a national market with a large customer list.

The Problem Outline

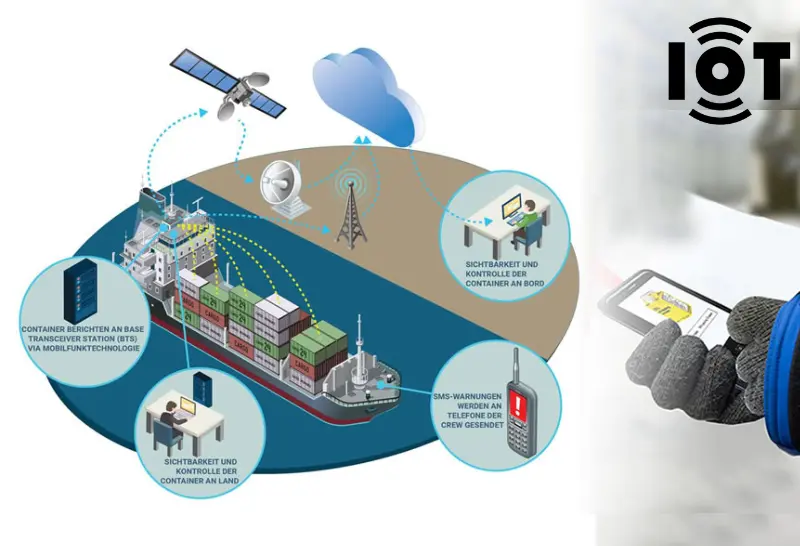

The client needed a centralised solution or platform for easy remote monitoring of the equipment situated at various locations. They needed to know all parameters, the alerts on the faults occurring via a user-friendly software that could be accessible by users simultaneously, in real-time over the same application.

The Solution Summary

The manufacturer needed to improve their market value primarily, and to be unique, distinguishable from the rest of the competition. They aimed at a quicker ROI by reducing cost of manual interventions and improve upon the efficient data trends.

The solution they needed had to improve customer satisfaction and brand value. So, we provided a modular solution for monitoring and controlling the critical parameters, which required 24×7 monitoring and improved the centralised visibility and also helps reduce maintenance costs. The IoT solution that integrated the machines on a platform offered value addition to improve performance and productivity. The efficiency of the equipment is also increased by tine and cost savings.

Outcome / Result

In solving the pain-points major advantages shift to the client –

- OEM has Software developed in-house matching customer requirements

- Tailor-made and customised solution made specific for client’s business needs

- Data driven results and trends greatly help in timely decision-making

- Solution experts with domain expertise work closely to provide value to your business

- Expectation based monitoring, custom based reporting improves results.

Takeaways

- Improves Asset Performance by 70%

- A 30% improvement in sales is possible

- Improves product quality by knowing instant alert trends by 40%

- Know your machine status and progress nearly instantly

- Increases Machine and AMC sign ups by 50%

Conclusion

- The client is provided a single unified software for all their needs

- An automated solution to monitor information remotely in real time

- Ensures quick go to market advantage and improves on AMC sign ups

- Saves on downtime and reduces equipment failures to minimum

Get to know more about our IoT solutions by filling up our enquiry form and sending it. Our team will revert to your enquiry as quickly as possible.

Client testimonials

“I’m so impressed with the t-Sense system and will be offering the IoT sensor on our products for customers. As a company we were looking for something to alert us when there is a discrepancy or failure in the equipment. The capability to integrate with all the devices and protocols makes it ideal for companies and customers. Thank you for installing a system we are comfortable with and a great value addition.”

– Chairman